Product advantages and features

The X-ray source adopts a closed X-ray tube, which has a long life and is maintenance-free.

It can be equipped with 90KV/110KV;

? A new generation of high-definition digital flat-panel detectors, high-resolution

design to obtain the best images in a very short time;

? Laser automatic navigation and positioning, quickly select the shooting location;

? X/Y/Z axis motion control, easy to operate;

? CNC inspection mode for rapid automatic inspection of multi-point arrays;

? Tilt angle: 60°, tilted for multi-angle detection, making it easier to detect sample

defects;

? Visual high-definition navigation window, easy to operate, quickly find the

detection target position;

? 450mm*500mm loading platform;

? The operation is simple and fast, you can quickly find the target defects and you

can get started with the two-hour training.

| Whole Machine Status | |

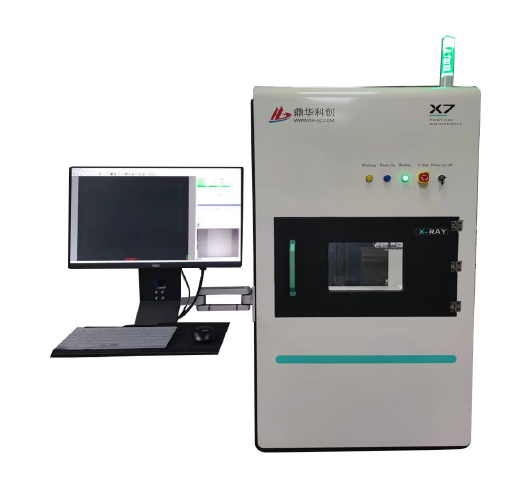

| Dimension | 1100 × 1200 × 2100 mm |

| Weight | Approx 1200 KG |

| Packing | 1300 × 1400 × 2200 mm |

| Open way | Manually |

| Uploading | Laboratory |

| Power supply | AC 220V 10A |

| Gross weight | About 1300 KG |

| Rated power | 1000W |

| Inspection | Off-line |

| Authorization | Password |

| Xray tubes | |

| Type | Sealed |

| Voltage | 90KV |

| Cooling | Wind |

| Current | 200?A |

| Focal spot size | 5um |

| Geometry magnification | 300 times |

| Imaging System | |

| Prober | Amorphous silicon flat panel detector |

| Effective imaging area | 156×128mm |

| Pixel matrix | 1536 ×1536 |

| Pixel size | 125μm |

| Spatial resolution | 4.0lp/mm |

| Frame rate | 30fps |

| AD conversion digits | 16bit |

| Data interface | Gigabit Ethernet |

| Trigger mode | Continuous acquisition, and pulse synchronization |

| X-ray energy range | 40KV-90KV |

| Radiation tolerance | 10000Gy |

| Protection level | IP65 |

| Size | 196 ×162 ×37.5 mm |

| Weight | 1.5KG |

| Consumption | 8W |

| Working temperature | 10-40? |

| Storage temperature | -10-55? |

| Operation humidity | 20-90%RH (No frost) |

| Storage humidity | 10-90%RH (No frost) |

| Image setting | Brightness, Contrast, Auto Gain and Exposure |

| Industrial Computer | |

| Display | 24-inch HD monitor |

| Operation method | Keyboard / mouse |

| Operating system | Windows 10, 64 bits |

| Hard disk / Memory | 1TB / 8G |

| Security | |

| Radiation amount | Steel-lead-steel protective structure is used, and the front door window is made of leaded glass for radiation protection. At any position 20mm away from the cabinet, the tested radiation dose equivalent rate is $\le 1\mu Sv/H$, in line with international standards |

| Lead glass observation window | Transparent lead glass, isolates radiation to observe the object being measured |

| Safety interlock | Two high-sensitivity limit switches are installed at the door opening positions used for equipment maintenance. Once the door is opened, the X-ray tube will automatically power off immediately. |

| Electromagnetic safety door switch | The observation window is equipped with an electromagnetic switch. When the X-ray is in working condition, the observation window cannot be opened. |

| Emergency button | Located next to the operating position, press it to cut off the power immediately in case of emergency. |

| Visual window | It has a visible transparent window, so that the sample condition can be observed directly from the window during the operation of the equipment. |

| X-ray tube protection | Only after turning off X-ray can you leave the software for other operations. |